Turn-key plants

One of Cleia’s strengths is its expertise and its capacity to supply turn-key industrial units: Brick works, roof tile plants or multi-product units.

We can build as well simple and efficient units as completely automated high-tech plants.

Learn more

Raw materials processing and fabrication

We define and deliver all the machinery required for preparation of raw materials and fabrication of products.

The first step of the ceramic process includes clays preparation. Raw materials extracted from the quarry are dosed, crushed then mixed in order to make up a clay body allowing the products shaping.

Learn more

Drying

Drying of ceramic products is often the trickiest production stage. Cleia has extensive experience and masters the various drying technologies to be implemented according to products to be manufactured and to available raw materials.

Our range or dryers:

- Zephyr®: Upgradable and innovative

- Sirocco: Rapid and robust

- Energy DT: Intelligent and Economic

- MV Tunnel: Large capacity and multi-products

Firing

We have developed a large range of kilns (tunnel or shuttle kilns) and of cars made up of prefired refractory pieces with firing temperature from 900 to 1300 °C.

We propose performing firing equipment with systems for reducing consumptions of all types of energy: gas, fuel oil, biomass,…

Our range of kilns and cars:

- Tradifast: Made up of fired clay bricks and with suspended roof

- Ecofast: Modular construction and short erection time

- Technofast: 100 % prefired refractory pieces

- Cars: Designed for bricks and roof tiles

Automatic handling

Our automatic circuits are designed according to the products to be handled at each stage of the manufacturing process.

Model handling circuits:

- Cutters: Standard cutting line and multiwires cutters

- Loaders: All kinds of dryers and products

- Stacking / Dehacking machines: Traditional or with robots

- Packaging: Customized packaging lines

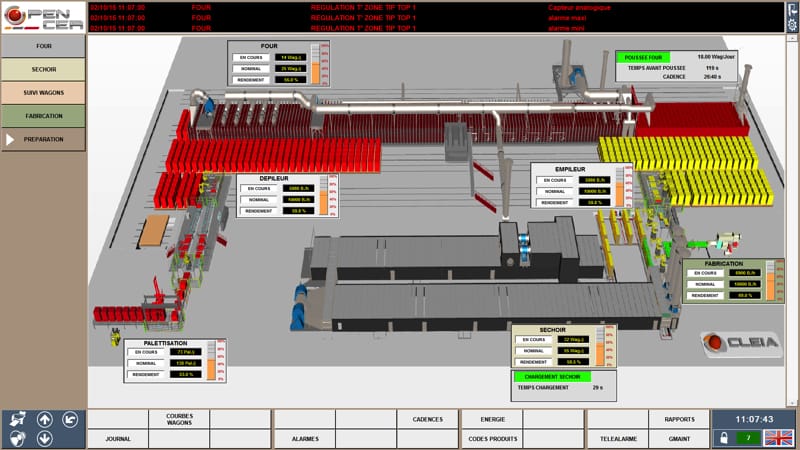

Supervision and process monitoring

In order to control the good running of regulation processes, we propose graphical interfaces, such as animated graphics, indicators, instantaneous and contextualized firing/ drying curves.

We are continuously adapting to our clients’ industrial process to provide customized solutions for each production site.